Your cart is currently empty!

Home

ARTIST | drafting | custom fabrication management

Custom design, curation, and management for interiors, furniture, and art objects in Los Angeles

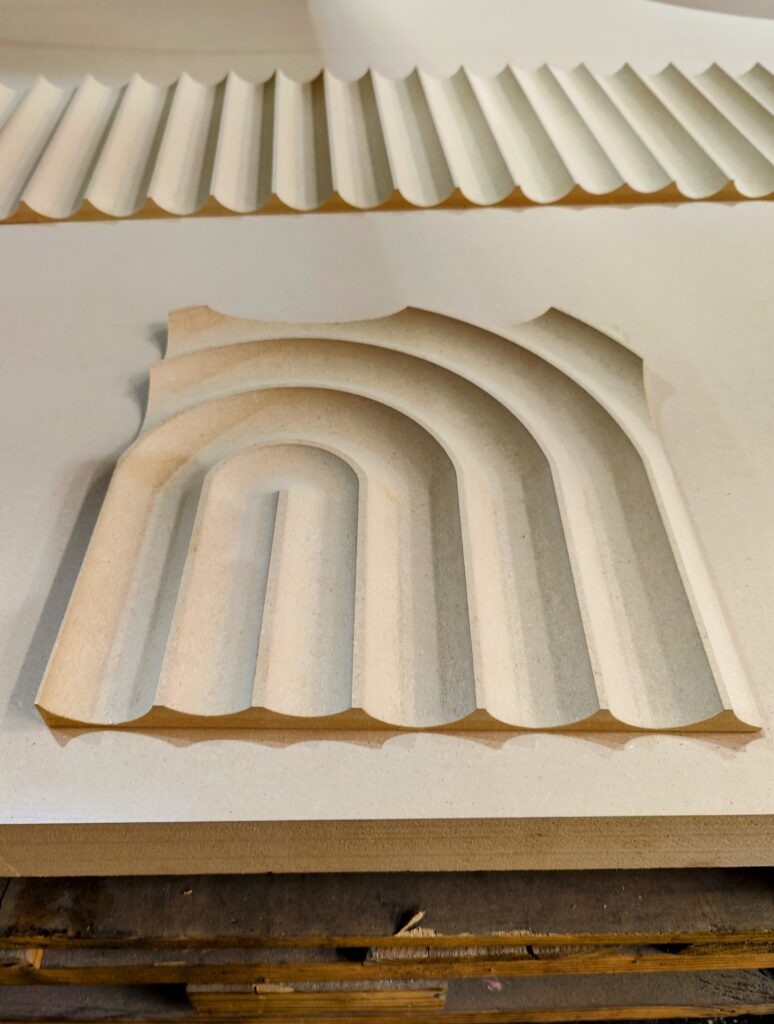

Custom Artwork

We offer custom interior art objects based on your desired size, material, and design. With experience in ceramics, tile, lighting, and sculpture, we can offer a wide range of options and fill your space with life.

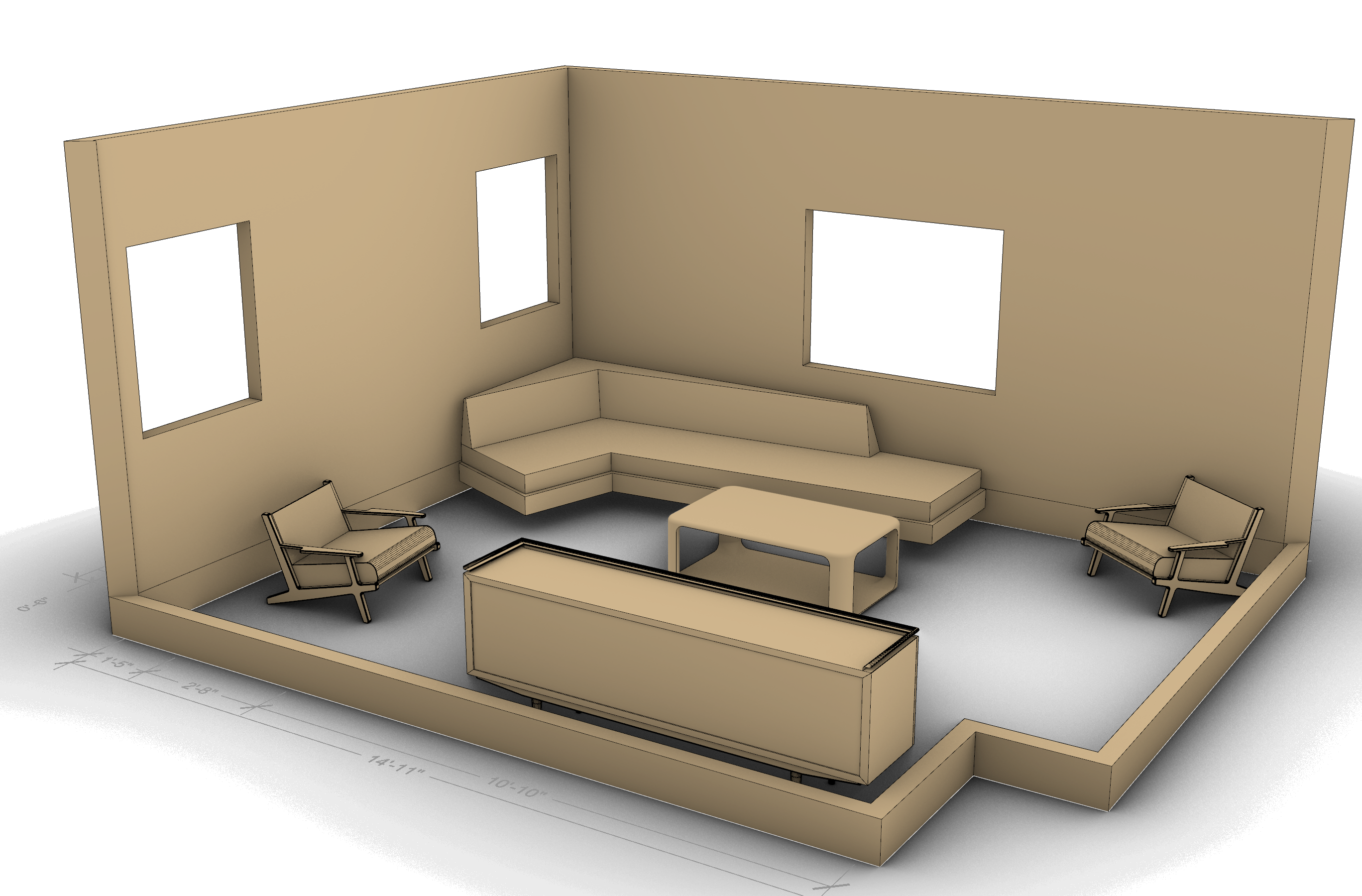

Design + Drafting Services

What kind of planning and specification is needed to make your idea come to life? With a network of peers working in Interior Fixtures, Heirloom Furniture, Architectural Millwork, Art Fabrication, and Experiential Services we can assemble the puzzle pieces to deliver your assets, no matter where in the process your project may be.

Fabrication + PM Services

What kind of planning and specification is needed to make your idea come to life? With a network of peers working in Interior Fixtures, Heirloom Furniture, Architectural Millwork, Art Fabrication, and Experiential Services we can assemble the puzzle pieces to deliver your assets, no matter where in the process your project may be.

Approach

01

Conceptualize & Design

The first step in fabricating large custom objects is to conceptualize and design the object. This involves creating loose drawings or and detailed 3D models that specify the object’s dimensions, materials, and construction details. This step ensures that everyone involved in the fabrication process has a clear understanding of what the object should look like and how it can be made.

02

Mis en Place

Once the design is finalized, the next step is to source the necessary materials. This may involve shopping for raw materials, such as metal, wood, or engineered composites, as well as ordering pre-fabricated components, such as beams, panels, or castings. The quality of the materials will have a significant impact on the quality of the finished product, so it is important to choose materials that are appropriate for the application and that meet the required specifications.

03

Fabrication Services

So, we have planned for all of the ingredients needed before we start cooking The next step is to cut and shape the materials according to the design specifications. This may involve using a variety of cutting tools, such as saws, lasers, or waterjets. The accuracy of the cutting process is critical to ensuring that the objects’ components fit together properly.

04

Finishing

The final step in the fabrication process is to finish the object. This may involve painting, sanding, or polishing the object. The finishing process will give the object its final appearance and will protect it from typical use. We’ve had the pleasure of working a wide range of specification, delivering traditional horn-polished tadelakt plaster to unforgiving 3 stage lowrider automotive finish.

05

Inspection and Testing

Once the object has been fabricated, it must be inspected and tested to ensure that it meets the required specifications. This may involve visual inspection, dimensional checks, and performance testing. The inspection and testing process will help to identify any defects that may need to be corrected before the object is put into service.

06

Project Management

We will work with you to create a personalized road map to meet our goals. We can handle logistics requests, crating, white glove load in+out labor, even offer storage capabilities if the site is not ready for delivery. Weekly stand-ups with updates, vendor management, and VE options are all packaged with our management services.